Construction Cost Estimating: Complete Guide to Methods, Accuracy, and Best Practices

Estimated reading time: 15 minutes

Key Takeaways

- Accurate construction cost estimating is crucial for setting realistic budgets and bidding strategies.

- Comprehensive estimates cover direct and indirect costs, contingencies, and escalation factors.

- Utilizing industry standards like AACE International ensures credibility and consistency.

- Different estimate classes help tailor the approach from early conceptual stages to definitive bids.

Table of contents

- Introduction: Why Construction Cost Estimating Matters

- Section 1: What is Construction Cost Estimating?

- Section 2: Classes and Types of Estimates (AACE Classes)

- Section 3: Estimating Methods for Building Cost Estimation

- Section 4: Step-by-Step Process for a Solid Cost Estimate

- Section 5: Tools, Software, and Data Sources for Construction Estimating

- Section 6: Accuracy, Risk, and Contingency in a Cost Estimate

- Section 7: Key Cost Drivers and External Factors

- Section 8: Quality Assurance and Validation

- Section 9: Communicating the Estimate

- Section 10: Common Mistakes and How to Avoid Them

- Section 11: Mini Worked Example

- Section 12: Templates and Resources for Building Cost Estimation

- Section 13: FAQs — Construction Cost Estimating

- Conclusion and Next Steps

Introduction: Why Construction Cost Estimating Matters

Construction cost estimating sits at the heart of every successful build. It is the engine behind budgets, bids, and profits. Good construction estimating saves time, prevents overruns, and empowers you to make confident go/no-go decisions.

In simple terms, it involves forecasting the total costs of a project by assessing materials, labor, equipment, overhead, and more.

- Helps secure work with the right price.

- Protects against unexpected cost spikes.

- Supports preconstruction decision-making.

This guide covers methods, estimate classes, process steps, key tools, and real-world examples.

Section 1: What is Construction Cost Estimating?

Construction cost estimating tracks a project from concept to closeout. It begins as a rough approximation and is refined into a detailed, defensible number.

Across the project lifecycle:

- Concept and feasibility: A rough idea of costs to test project viability.

- Schematic and design development: Improved drawings lead to tighter estimates.

- Construction documents and buyout: Detailed takeoffs and fixed pricing from vendors.

- Construction and closeout: Ongoing cost control and final account reconciliation.

Core cost components include:

- Direct costs (materials, labor, equipment, subcontracts).

- Indirect costs (overhead, supervision, insurance, bonds).

- Profit margins.

- Allowances for undefined work.

- Contingency for known-unknowns.

- Escalation accounting for inflation and time-based factors.

Typical deliverables: An estimate summary, detailed line items with quantities and unit prices, a Basis of Estimate (BOE), and documented assumptions and exclusions.

Best practices include adhering to standards from AACE International and using frameworks such as CSI MasterFormat.

Section 2: Classes and Types of Estimates (AACE Classes)

AACE International defines five classes of estimates, ranging from very early, rough approximations to detailed, near-final budgets.

Estimate classes and typical accuracy ranges:

- Class 5 (Order of Magnitude): Limited scope (0–2%) with accuracy ranging roughly from −50% to +100%.

- Class 4 (Feasibility/Screening): Early design stage (1–15%) with accuracy around −30% to +50%.

- Class 3 (Budget/Authorization): Schematic to early design development (10–40%) with accuracy about −20% to +30%.

- Class 2 (Control/Intermediate): Late design development (30–70%) with accuracy roughly −15% to +20%.

- Class 1 (Definitive): Construction documents stage (65–100%) with accuracy about −5% to +15%.

When to use each class:

- Class 5 for feasibility studies and early go/no-go decisions.

- Class 4 for concept selection and early funding.

- Class 3 for setting budgets and design-to-budget validations.

- Class 2 for pre-bid and procurement planning.

- Class 1 for firm bids and final buyouts.

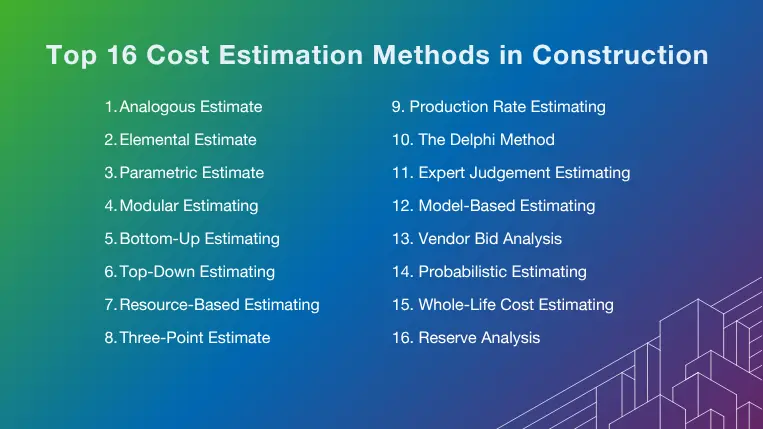

Section 3: Estimating Methods for Building Cost Estimation

Select the method or a combination of methods that best fits your project’s stage:

- Top-down (analogous) estimating:

- Uses historical project costs, normalized by size, location, and time.

- Pros: Quick with minimal data.

- Cons: May overlook unique project specifics.

- Parametric estimating:

- Relies on cost drivers such as cost per square foot or unit.

- Pros: Scalable and easily updated.

- Cons: Requires careful validation of parameters.

- Assemblies estimating:

- Uses system-based pricing (e.g., slab with rebar and finishing) for schematic designs.

- Faster than a full bottom-up approach.

- Bottom-up (unit-rate build-ups):

- Detailed takeoff per item and unit-rate build-ups for labor, materials, and equipment.

- Pros: Offers maximum accuracy and traceability.

- Cons: Time intensive and data heavy.

- Probabilistic estimating:

- Incorporates three-point estimates and Monte Carlo simulations to determine confidence levels (e.g., P50, P80).

- Pros: Clearly communicates risk and uncertainty.

- Cons: Requires detailed input data and statistical tools.

- 5D BIM-driven estimating:

- Links model quantities from 3D BIM to cost data, integrating the “5th dimension”.

- Enhances traceability and update speed through design changes.

Discover more details in this construction cost estimating guide.

Section 4: Step-by-Step Process for a Solid Cost Estimate

- Gather inputs:

- Drawings and specifications (latest issue only).

- BIM model and model element table.

- Geotechnical reports, surveys, and site logistics plan.

- Project schedule with milestones and phasing.

- Procurement strategy details (e.g., CM at Risk, Design-Bid-Build).

- Build the Work Breakdown Structure (WBS):

- Use standard cost codes like CSI MasterFormat or Uniformat.

- Align WBS with the construction approach.

- Perform quantity takeoff:

- Apply clear measurement rules and document assumptions.

- Double-check key quantities such as concrete, steel, or façade elements.

- Calculate unit cost build-ups:

- Labor: Factor in productivity rates and wages.

- Materials: Use current supplier quotes and consider lead times.

- Equipment: Compare owned versus rental costs.

- Subcontracts: Gather and compare bids from at least three vendors.

- Add indirects and markups:

- Include general conditions, overhead, and profit margins.

- Factor in insurance, bonds, and permits.

- Plan for allowances, alternates, contingencies, and escalation:

- Set allowances for incomplete designs.

- Include alternates for potential value engineering.

- Apply a contingency percentage based on project risk.

- Adjust for escalation to cover inflation and market changes.

- Adjust for time and location with indices:

- Utilize indices like ENR CCI and BLS PPI/ECI.

- Normalize past costs to current market conditions.

- Compile the Basis of Estimate (BOE):

- Document all assumptions, exclusions, and pricing dates.

- List data sources and indices used in the estimation.

- Check, review, and sign off:

- Conduct a peer review and reconcile discrepancies.

- Ensure the final numbers are documented and approved.

Additional insights on this process can be found here.

Section 5: Tools, Software, and Data Sources for Construction Estimating

Enhance your estimating workflow with the right stack of tools and data:

- Takeoff and Estimating Tools:

- CostX, PlanSwift, and Bluebeam Revu for quantity measurements.

- Sage Estimating, ProEst, and WinEst for cost calculation.

- Excel or Google Sheets for custom unit-rate build-ups.

- Model-based takeoff tools for effective 5D BIM integration.

- Cost Databases and Price Data:

- Refer to RSMeans cost data for assembly and unit prices.

- Utilize vendor and subcontractor quotes for live pricing updates.

- Review manufacturer price lists and internal historical databases.

- BIM Integrations:

- Link model quantities directly to cost codes.

- Use APIs to sync real-time design changes and maintain version control.

Section 6: Accuracy, Risk, and Contingency in a Cost Estimate

Managing risk and uncertainty is key to a credible estimate:

- Contingency vs. Management Reserve vs. Escalation:

- Contingency covers known-unknowns within the project scope.

- Management reserve is allocated for unforeseen, larger risks beyond the project’s scope.

- Escalation accounts for cost increases over time due to inflation.

- Risk Analysis Tools:

- Sensitivity analysis to pinpoint key cost drivers.

- Monte Carlo simulations to derive statistical cost ranges (e.g., P50, P80).

- Risk registers to identify, track, and manage potential issues.

- Setting Contingency:

- Apply a higher contingency in early project stages and reduce it as more details emerge.

Learn more about managing risks at AACE International.

Section 7: Key Cost Drivers and External Factors

External factors largely determine how your budget evolves:

- Market and Location:

- Supply chain conditions, tariffs, and lead times.

- Local wage rates, labor rules, and taxation.

- Site logistics and access affecting crane and material delivery times.

- Design and Scope:

- The level of design completeness and project complexity directly impact costs.

- Custom designs or sustainable initiatives (e.g., LEED) require tailored estimates.

- Delivery Methods:

- The choice between CMAR, DBB, or DB affects cost risk distribution and scheduling.

- Prefabrication may reduce onsite labor but increase factory costs.

- Weather and Seasonality:

- Plan for seasonal impacts such as weather delays or protective measures.

Section 8: Quality Assurance and Validation

- Peer Review and Reconciliation:

- Have a second estimator independently review the numbers.

- Reconcile estimates with those provided by the design team or owner.

- Benchmarking:

- Compare against similar past projects and adjust for regional differences.

- Checklists and Controls:

- Implement scope checklists, math checks, and quote logs to prevent errors.

Section 9: Communicating the Estimate

Effectively presenting your estimate is as crucial as preparing it:

- Clear Summaries and Visuals:

- Executive summaries should highlight total costs, key drivers, and confidence intervals.

- Include pie charts or bar graphs for clear visual breakdowns.

- Decision Support:

- Offer alternate solutions and value engineering options.

- Provide lifecycle cost analysis for long-term planning.

- Delivery Tools:

- Integrate cost-loaded schedules and cash flow curves for a comprehensive view.

- Ensure compatibility with ERP and project control systems.

Section 10: Common Mistakes and How to Avoid Them

- Frequent Errors:

- Omitting significant scope elements such as site utilities or testing.

- Relying on outdated unit rates and quotes.

- Ignoring escalation factors and volatility in pricing.

- Misclassifying contingency as profit or vice versa.

- Lack of a detailed BOE with clear assumptions and exclusions.

- How to Avoid Them:

- Implement a standardized checklist for every estimate.

- Regularly update pricing data and index costs to the current bid date.

- Conduct thorough peer reviews and reconcile any differences.

Section 11: Mini Worked Example (Construction Estimating)

Example Scope: 6-inch concrete slab on grade for 10,000 square feet. Prices are illustrative and based on market rates (e.g., “Q2 2025, US Northeast”).

Quantity Takeoff:

- Area: 10,000 SF

- Thickness: 6 inches (0.5 feet)

- Volume: 10,000 SF x 0.5 ft = 5,000 cubic feet ≈ 185.2 cubic yards

Direct Costs:

- Concrete: 185.2 CY x $150/CY = $27,780

- Rebar (approx. 4 lb/SF yielding 20 tons): 20 tons x $1,200/ton = $24,000

- Formwork/edge: 600 LF x $8/LF = $4,800

- Labor (place/finish): 185.2 CY x $95/CY = $17,594

- Equipment (lump sum): $3,500

- Subtotal Direct: $77,674

Indirects and Markups:

- General Conditions (5%): $3,884

- Overhead (5%): $3,884

- Profit (7%): $5,437

- Insurance/Bond (1%): $777

- Subtotal with Markups: $91,656

Contingency and Escalation:

- Contingency (10% for Class 3): $9,166

- Escalation (3%): $2,750

- Final Assembly Total: $103,572

Notes: Include joints, curing compounds, and testing where applicable. Confirm rebar spacing and account for a 5% waste factor.

Reference: Construction Cost Estimating Guide

Section 12: Templates and Resources for Building Cost Estimation

- Starter Templates:

- Basis of Estimate (BOE) template outlining scope, assumptions, pricing date, indices, inclusions, exclusions, and risks.

- Estimate checklist covering CSI divisions, permits, temporary works, and testing.

- WBS starter pack with standard cost codes adaptable for project needs.

- Unit rate build-up sheets for labor, materials, and equipment.

- Reading List:

Section 13: FAQs — Construction Cost Estimating

Q1: What is construction cost estimating and why is it important?

A: It is the process of forecasting all costs for a construction project—including materials, labor, equipment, overhead, and profit. It sets realistic budgets, supports bids, and minimizes financial risks.

Q2: What accuracy can I expect for each estimate class?

A: Early Class 5 estimates can vary widely (approximately −50% to +100%). As the design matures, accuracy improves, with Class 1 estimates typically within −5% to +15%.

Q3: How much contingency should be included at different design stages?

A: Higher contingencies are advised in early stages (Class 5/4) due to greater uncertainty, while more detailed stages (Class 2/1) allow for lower contingencies. Base it on a detailed risk register.

Q4: How do I adjust an estimate for location and inflation?

A: Use location factors and cost indices like ENR Construction Cost Index and BLS Producer Price Index to normalize past costs to current market conditions. Apply escalation adjustments for anticipated inflation.

Q5: What is the difference between escalation and contingency?

A: Escalation covers cost increases over time due to market fluctuations and inflation, while contingency addresses uncertainties within the project scope.

Q6: How does BIM improve construction cost estimating?

A: BIM facilitates 5D workflows by linking model quantities to costs, accelerating takeoffs, and reducing manual errors through dynamic updates.

Conclusion and Next Steps

Robust construction cost estimating drives better budgeting, more competitive bids, and enhanced risk management. Adopting the correct estimate class, method, and a well-documented BOE is essential.

Next steps:

- Download the provided templates to standardize your estimating process.

- Stay updated with current market indices and cost data.

- Consider consulting experts to refine your workflow and integrate 5D BIM solutions.